NCSIMUL then simulates to the user the entire manufacturing process, including the links amongst different strategies, ensuring absolute security for the manufacturing process.

WORKNC to NCSIMUL - 1 | WORKNC 2022

WORKNC now offers integration with NCSIMUL Standard for post-processed NC code simulation and verification. The entire machining environment is seamlessly transfered from WORKNC to NCSIMUL, including the part geometry, stock model, fixtures, tooling list, and the NC code of the strategies applied.

NCSIMUL then simulates to the user the entire manufacturing process, including the links amongst different strategies, ensuring absolute security for the manufacturing process.

WORKNC to NCSIMUL - 2 | WORKNC 2022

WORKNC now offers integration with NCSIMUL Standard for post-processed NC code simulation and verification. The entire machining environment is seamlessly transfered from WORKNC to NCSIMUL, including the part geometry, stock model, fixtures, tooling list, and the NC code of the strategies applied.

NCSIMUL then simulates to the user the entire manufacturing process, including the links amongst different strategies, ensuring absolute security for the manufacturing process.

Parallel Finishing Spiral Transition | WORKNC 2022

The now consolidated, modern Parallel Finishing toolpath completes the functionality in replacing Z-Level Finishing and Planar Finishing. Much faster and more reliable, this toolpath is the technological base for all Hexagon 3-Axis toolpath compensation. Supporting any tool shape compensation, the new spiral option calculates in a quarter of the time of the previous alternative.

Contour rest machining - legacy vs new | WORKNC 2022

Rest Finishing a part just got a lot simpler and more powerful with WORKNC 2022.0 Contour Remachining with Advanced Toolform, a technology that allows the user to select any tool shape. This toolpath is also now 3 times faster when using the updated 3D Stock as a reference, allowing for the precise detection of rest material, even when the previous processes used circle-segment tools, used smoothing radius parameters, or were applied from a different angle.

Contour rest machining | WORKNC 2022

Rest Finishing a part just got a lot simpler and more powerful with WORKNC 2022.0 Contour Remachining with Advanced Toolform, a technology that allows the user to select any tool shape. This toolpath is also now 3 times faster when using the updated 3D Stock as a reference, allowing for the precise detection of rest material, even when the previous processes used circle-segment tools, used smoothing radius parameters, or were applied from a different angle.

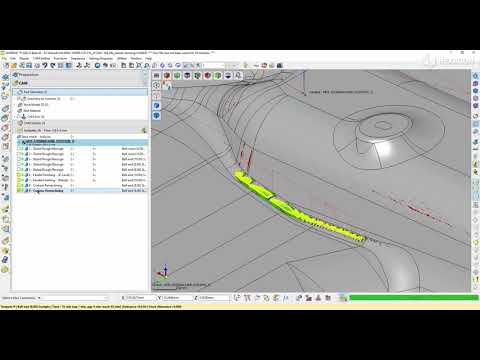

Curve Profiling | WORKNC 2022

WORKNC introduces modern technology for wireframe machining. Even the most complex jobs include a portion of simple, prismatic machining. Those are normally executed with wireframe-based toolpaths. Curve Profiling brings robust tool radius compensation tools that elevate the game for WORKNC users.

5-Axis parallel finishing - 1 | WORKNC 2022

WORKNC 2022.0 elevates the game in 5-Axis strategies using any tool shape. Strategies such as 5-Axis Offset, 5-Axis Parallel Finishing, and 5-Axis Curve Machining allow the user to create fast, reliable toolpath with barrel cutters, lens cutters and any other user defined shapes. These tools allow for much improved surface finishing with reduced cycle times.

5-Axis parallel finishing - 2 | WORKNC 2022

WORKNC 2022.0 elevates the game in 5-Axis strategies using any tool shape. Strategies such as 5-Axis Offset, 5-Axis Parallel Finishing, and 5-Axis Curve Machining allow the user to create fast, reliable toolpath with barrel cutters, lens cutters and any other user defined shapes. These tools allow for much improved surface finishing with reduced cycle times.

5-Axis parallel finishing - 3 | WORKNC 2022

WORKNC 2022.0 elevates the game in 5-Axis strategies using any tool shape. Strategies such as 5-Axis Offset, 5-Axis Parallel Finishing, and 5-Axis Curve Machining allow the user to create fast, reliable toolpath with barrel cutters, lens cutters and any other user defined shapes. These tools allow for much improved surface finishing with reduced cycle times.

5-Axis offset machining -1 | WORKNC 2022

WORKNC 2022.0 elevates the game in 5-Axis strategies using any tool shape. Strategies such as 5-Axis Offset, 5-Axis Parallel Finishing, and 5-Axis Curve Machining allow the user to create fast, reliable toolpath with barrel cutters, lens cutters and any other user defined shapes. These tools allow for much improved surface finishing with reduced cycle times.

5-Axis offset machining - 2 | WORKNC 2022

WORKNC 2022.0 elevates the game in 5-Axis strategies using any tool shape. Strategies such as 5-Axis Offset, 5-Axis Parallel Finishing, and 5-Axis Curve Machining allow the user to create fast, reliable toolpath with barrel cutters, lens cutters and any other user defined shapes. These tools allow for much improved surface finishing with reduced cycle times.